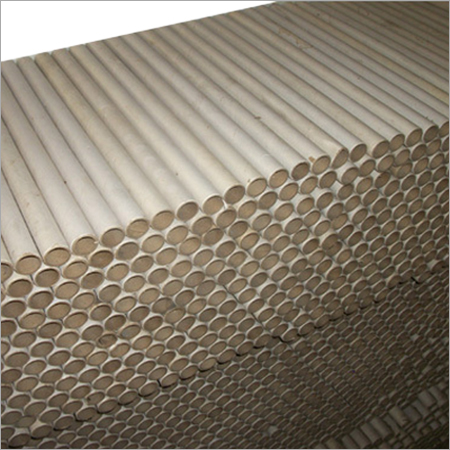

Paper Core Tubes

Price 40 INR/ Kilograms

Paper Core Tubes Specification

- Product Type

- Paper Core Tubes

- Material

- Paperboard / Kraft Paper

- Shape

- Round

- Usage

- Industrial Packaging, Textile Yarn Winding, Paper Winding

- Surface Handling

- Plain, Smooth Finish

- Tube Cap

- Without Cap

- Volume

- Customized as per requirement

- Diameter

- 25 mm - 300 mm

- Thickness

- 2 mm - 15 mm

- Color

- Brown

- Usage & Applications

- Used in textile, paper mills, adhesive tapes, film and foil winding

- Size

- Customized (Length as per client requirement)

- Inner Surface

- Smooth / can be customized

- Length Range

- 90 mm - 4000 mm

- Printing Options

- Available on request

- Core Type

- Spiral / Parallel Wound

- Eco-Friendly

- 100% Recyclable

- Moisture Resistance

- Yes

- Compression Strength

- High, suitable for heavy-duty applications

- Minimum Order Quantity

- As per requirement

Paper Core Tubes Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 10000 Kilograms Per Day

- Delivery Time

- 2-4 Days

- Sample Available

- Yes

- Packaging Details

- customized packing

- Main Domestic Market

- North India

About Paper Core Tubes

Owing to our rich expertise in this domain, we are able to provide supreme grade collection of Paper Core Tubes. Finding their wide applications in various industries, these tubes are ideal for packaging of fabrics, foil, ribbons, threads etc. The offered tubes are manufactured using quality-assured paper and state-of-the-art techniques by our skilled professionals. In addition, these Paper Core Tubes can be availed from us at cost effective rates within prescribed time frame.

Key Points:

- Excellent finish

- High strength

- Tear resistance

- Enhanced durability

Customizable Performance for Industrial Needs

Our Paper Core Tubes can be customized to meet specific requirements in terms of size, thickness, and inner surface texture. Designed for robust usage, they offer high compression strength suitable for demanding applications across textile, paper, and packaging industries. Their moisture-resistant quality makes them reliable for long-term use in various environments.

Eco-Friendly and Versatile Solutions

Manufactured from recyclable materials, these tubes present an environmentally conscious choice for businesses. The spiral and parallel wound construction enhances durability and flexibility, ensuring suitability for applications such as yarn winding, film and foil wrapping, and adhesive tape cores. The smooth finish and plain surface handling further improve utility and product presentation.

FAQs of Paper Core Tubes:

Q: How are Paper Core Tubes manufactured and what customization options are available?

A: Paper Core Tubes are produced using spiral or parallel winding techniques with paperboard or kraft paper. Clients can customize length (90 mm - 4000 mm), diameter (25 mm - 300 mm), thickness (2 mm - 15 mm), inner surface, and printing requirements to best suit their industrial needs.Q: What are the benefits of using moisture-resistant, high-compression Paper Core Tubes for industrial applications?

A: Their moisture resistance ensures tube integrity during storage and transport, while high compression strength guarantees safe handling of heavy loads. This makes them ideal for applications in textile yarn winding, paper mills, and heavy-duty packaging.Q: Can these Paper Core Tubes be ordered in custom sizes and volumes for specific uses?

A: Yes, size, volume, and dimensional specifications are fully customizable, allowing each order to match precise client requirements for industrial, textile, or packaging operations.Q: Which industries commonly utilize these Paper Core Tubes and for what purposes?

A: Industries such as textile manufacturing, paper mills, film and foil packaging, and adhesive tape production frequently use these tubes for winding and storage due to their strength, smooth finish, and adaptability.Q: What makes these Paper Core Tubes an eco-friendly packaging choice?

A: They are produced from 100% recyclable paperboard or kraft paper, helping reduce environmental impact and promoting sustainable packaging practices.Q: Are printing and branding options available on the Paper Core Tubes?

A: Yes, customized printing and logos can be added on request to enhance brand visibility and meet specific product identification needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Tubes Category

Packaging Paper Tube

Price 40 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Tube Cap : Other, Plastic or Metal (optional)

Volume : Other, 501000 ml (varies by size)

Thickness : 13 mm (customizable)

Color : Other, Brown

Carpet Spiral Paper Tubes

Price 40 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Tube Cap : Other, Open

Volume : Other, Customizable

Thickness : 210 mm

Color : Other, Brown

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS