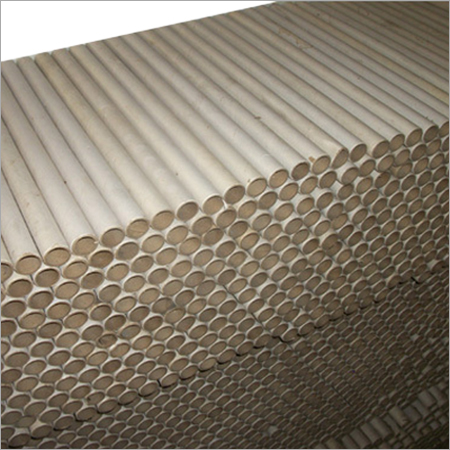

Carpet Spiral Paper Tubes

Price 40 INR/ Kilograms

Carpet Spiral Paper Tubes Specification

- Product Type

- Carpet Spiral Paper Tubes

- Material

- Kraft Paper

- Shape

- Round

- Usage

- Carpet Rolling and Packaging

- Surface Handling

- Smooth Finish

- Tube Cap

- Open

- Volume

- Customizable

- Diameter

- 2-8 Inches

- Thickness

- 2-10 mm

- Color

- Brown

- Usage & Applications

- Used in carpet manufacturing and textile industry

- Size

- Customized sizes available

Carpet Spiral Paper Tubes Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 10000 Kilograms Per Day

- Delivery Time

- 2-4 Days

- Sample Available

- Yes

- Packaging Details

- customized packing

- Main Domestic Market

- North India

About Carpet Spiral Paper Tubes

Having customer satisfaction as our primary goal, we are instrumental in offering the best quality array of Carpet Spiral Paper Tubes. These tubes can be availed from us at rock bottom prices in several dimensions. The provided tubes are used for packaging of various kinds of fabrics and carpet cloth. With the help of sophisticated techniques, the offered Carpet Spiral Paper Tubes are manufactured by our adept professionals using quality-examined paper.

Key Points:

- Uniform thickness

- Accurate dimension

- Longer life

- Perfect finish

Eco-Friendly & High Performance

Our Carpet Spiral Paper Tubes are made with recyclable and biodegradable kraft paper. Designed for sustainability, these tubes not only support environmentally responsible practices but also offer high load-bearing capacity suitable for carpet industry usage. Each tube is ISO certified, ensuring consistent quality and reliability.

Customizable for Industry Needs

Versatility is key. Lengths, diameters, and thicknesses can be tailored to match your carpet rolling or packaging specifications. From a robust clean cut finish to core ID tolerance of 0.5 mm, every detail is optimized for your business needs, ensuring smooth handling, efficient storage, and precise application.

FAQs of Carpet Spiral Paper Tubes:

Q: How are Carpet Spiral Paper Tubes typically used in the carpet and textile industry?

A: These spiral-wound kraft paper tubes serve as reliable cores for rolling and packaging carpets, providing structural support during transport and storage. Their high load-bearing capacity and moisture resistance make them suitable for demanding manufacturing workflows.Q: What makes these tubes eco-friendly and sustainable for businesses?

A: Our tubes are crafted from recyclable and biodegradable kraft paper, minimizing environmental impact. They can be responsibly disposed of or recycled after use, aligning with sustainability initiatives in the industry.Q: When should I opt for customized sizes or thicknesses for my application?

A: Customized tubes are ideal when handling carpets of varying widths and weights, ensuring optimal fit and support. Adjustable diameters, lengths, and thicknesses cater to specific manufacturing and packaging requirements.Q: Where should Carpet Spiral Paper Tubes be stored to maintain their quality?

A: To preserve their moisture resistance and structural integrity, store the tubes in a dry place, away from direct exposure to humidity or water. Proper storage enhances their longevity and performance.Q: What is the manufacturing process of spiral-wound paper tubes?

A: The process involves winding layers of kraft paper in a spiral pattern around a mandrel, followed by polishing for a smooth finish. Precision cutting ensures clean ends and adherence to ISO quality standards, delivering consistent, reliable tubes.Q: What benefits does the polished and smooth surface offer for handling and packaging?

A: A polished and smooth finish makes the tubes easier to handle and load carpets onto, reducing the risk of snagging or surface damage to textile products, and improving overall operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Tubes Category

Paper Core Tubes

Price 40 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Size : Customized (Length as per client requirement)

Usage : Other, Industrial Packaging, Textile Yarn Winding, Paper Winding

Diameter : 25 mm 300 mm

Tube Cap : Other, Without Cap

Packaging Paper Tube

Price 40 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Size : Customized Length

Usage : Other, Packaging and Storage

Diameter : 30100 mm (customizable)

Tube Cap : Other, Plastic or Metal (optional)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS